Comprehending the Value of Foam Control in Food and Drink Handling

Comprehending the Value of Foam Control in Food and Drink Handling

Blog Article

A Comprehensive Overview to Executing Foam Control Solutions in Your Operations

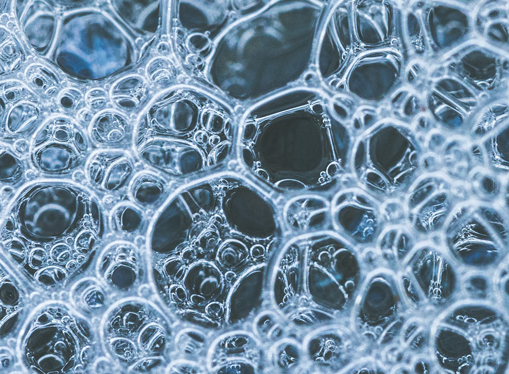

Efficient foam control is a critical facet of operational effectiveness that commonly goes overlooked. Comprehending the complexities of foam generation can significantly impact both efficiency and product quality. This overview describes the numerous challenges positioned by foam and the diverse remedies readily available, providing a framework for selecting and executing one of the most ideal strategies. By taking a look at crucial aspects such as application compatibility and employees training, organizations can optimize their foam management efforts. As we discover these parts, the capacity for transformative enhancements in your procedures ends up being obvious. What steps will you take following?

Comprehending Foam Challenges

Foam challenges are a substantial worry across various sectors, affecting operational performance and item high quality. The formation of too much foam can impede procedures such as mixing, transport, and storage space, leading to raised downtime and waste. In markets like food and beverage, pharmaceuticals, and petrochemicals, foam can hinder manufacturing lines, causing item disparities and contamination risks.

Moreover, foam can block equipment performance, resulting in pricey repair work and maintenance. In wastewater treatment, foam can disrupt clarifier procedures, resulting in reduced treatment effectiveness and governing compliance concerns.

Understanding the underlying root causes of foam generation is crucial for efficient monitoring. Elements such as surfactants, temperature level fluctuations, and anxiety degrees can all contribute to foam production. Recognizing these elements enables markets to apply targeted techniques that decrease foam development while keeping item stability.

Kinds Of Foam Control Solutions

Mechanical remedies include using tools such as foam skimmers or defoamers. These tools physically eliminate foam from the surface area of fluids, thereby preventing overflow and preserving optimum degrees in activators and containers. Chemical options, on the other hand, consist of the application of defoaming representatives-- materials that interrupt the foam structure, leading to its collapse. These agents can be silicone-based, organic, or aqueous, each offering unique advantages depending upon the application setting.

Finally, functional techniques concentrate on procedure modifications. This might entail changing equipment criteria, such as temperature level and pressure, or altering the flow prices of fluids to reduce foam generation. Executing good housekeeping practices can also mitigate foam formation by lowering impurities that contribute to foam stability.

Selecting the suitable foam control service entails analyzing the details requirements of the operation, including the kind of process, the qualities of the products included, and safety factors to consider.

Picking the Right Products

Selecting the best foam control items needs a thorough understanding of the particular application and its unique challenges. Aspects such as the kind of foam, the environment in which it occurs, and the desired end result all play critical duties in product selection. Foam Control. In sectors like food processing, it is crucial to select food-grade defoamers that conform with safety and security policies while successfully handling foam.

In addition, consider the viscosity Go Here of the fluid where the foam issue exists. Some products are developed for low-viscosity applications, while others are tailored for thicker liquids. Compatibility with existing processes is one more critical aspect; the picked foam control representatives ought to incorporate flawlessly without interrupting overall operations.

One more essential factor is the technique of application. Some items may need dilution, while others can be used straight. Assessing the ease of usage and the called for dosage can offer insights right into the product's efficiency and cost-effectiveness.

Application Strategies

Effective application approaches for foam control solutions require a systematic approach that aligns product choice with functional needs. The very first step includes an extensive evaluation of the processes where foam occurs, identifying specific areas that require treatment. By engaging cross-functional teams, consisting of production, quality, and design guarantee, organizations can gather understandings that notify the choice of the most reliable foam control products.

Next, it is crucial to establish clear objectives for foam decrease, making sure that these goals are measurable and possible. This may involve specifying acceptable foam degrees and the timelines for execution. Educating workers on the properties and application techniques of chosen foam control agents is just as crucial, as proper use is crucial for ideal outcomes.

In addition, integrating foam control options right into existing workflows needs cautious preparation. Ultimately, a well-structured technique will improve functional performance while effectively handling foam-related difficulties.

Monitoring and Examining Performance

Monitoring and assessing the efficiency of foam control options is essential for ensuring that carried out methods generate the wanted outcomes. This procedure involves methodical data collection and analysis to evaluate the performance of foam control agents and strategies. Secret performance indications (KPIs) should be established prior to execution, allowing for a clear baseline versus which to gauge progress.

Examining performance additionally requires periodic reviews of foam control treatments and representative more helpful hints effectiveness. This can be completed through sampling and testing, allowing operators to determine if current remedies are fulfilling functional demands. It is essential to solicit responses from team members who communicate with these systems daily, as their understandings can expose operational subtleties that measurable data might forget.

Eventually, an organized surveillance and analysis structure assists determine required adjustments, ensuring that foam control solutions continue to be reliable, inexpensive, and lined up with business objectives.

Final Thought

To conclude, effective foam control solutions are crucial for maximizing functional performance and preserving product top quality. A comprehensive understanding of foam navigate to this site obstacles, incorporated with the selection of suitable items and application techniques, facilitates the effective administration of foam generation. Establishing quantifiable KPIs and spending in workers educating further enhance the efficiency of foam control steps. Regular tracking and evaluation ensure continual enhancement, ultimately causing an extra streamlined and effective operational atmosphere.

Executing good housekeeping methods can additionally mitigate foam formation by lowering contaminants that contribute to foam security.

Choosing the best foam control items calls for a complete understanding of the details application and its unique challenges (Foam Control).Successful execution approaches for foam control solutions require a systematic strategy that aligns product choice with operational demands.In verdict, efficient foam control remedies are essential for optimizing functional effectiveness and keeping product high quality. An extensive understanding of foam challenges, integrated with the selection of ideal items and application approaches, facilitates the successful administration of foam generation

Report this page